(Automated) production machines and production solutions

Production is a critical component of any manufacturing process, having suitable machinery can make all the difference in ensuring products are made efficiently and with the highest quality at the lowest costs. For 55 years, ATD Machinery has been a trusted partner in the industry, providing expertise and innovation in the design and manufacture of production machinery.

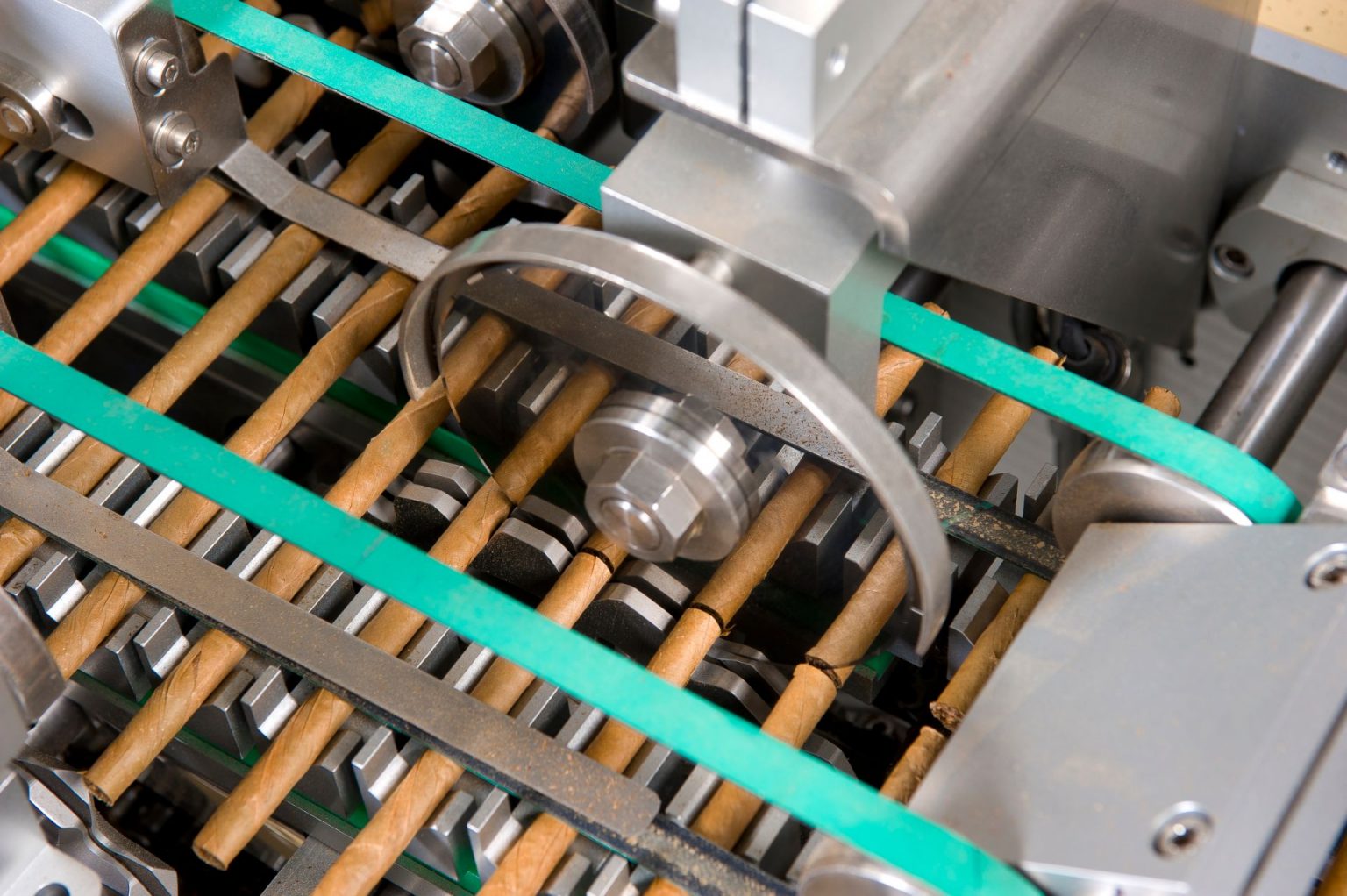

With a focus on precision and attention to detail, ATD Machinery has become a leading name in the field, trusted by companies worldwide to create machinery that meets their production needs. Our experience has been built on making cigars, but our capabilities go far beyond.

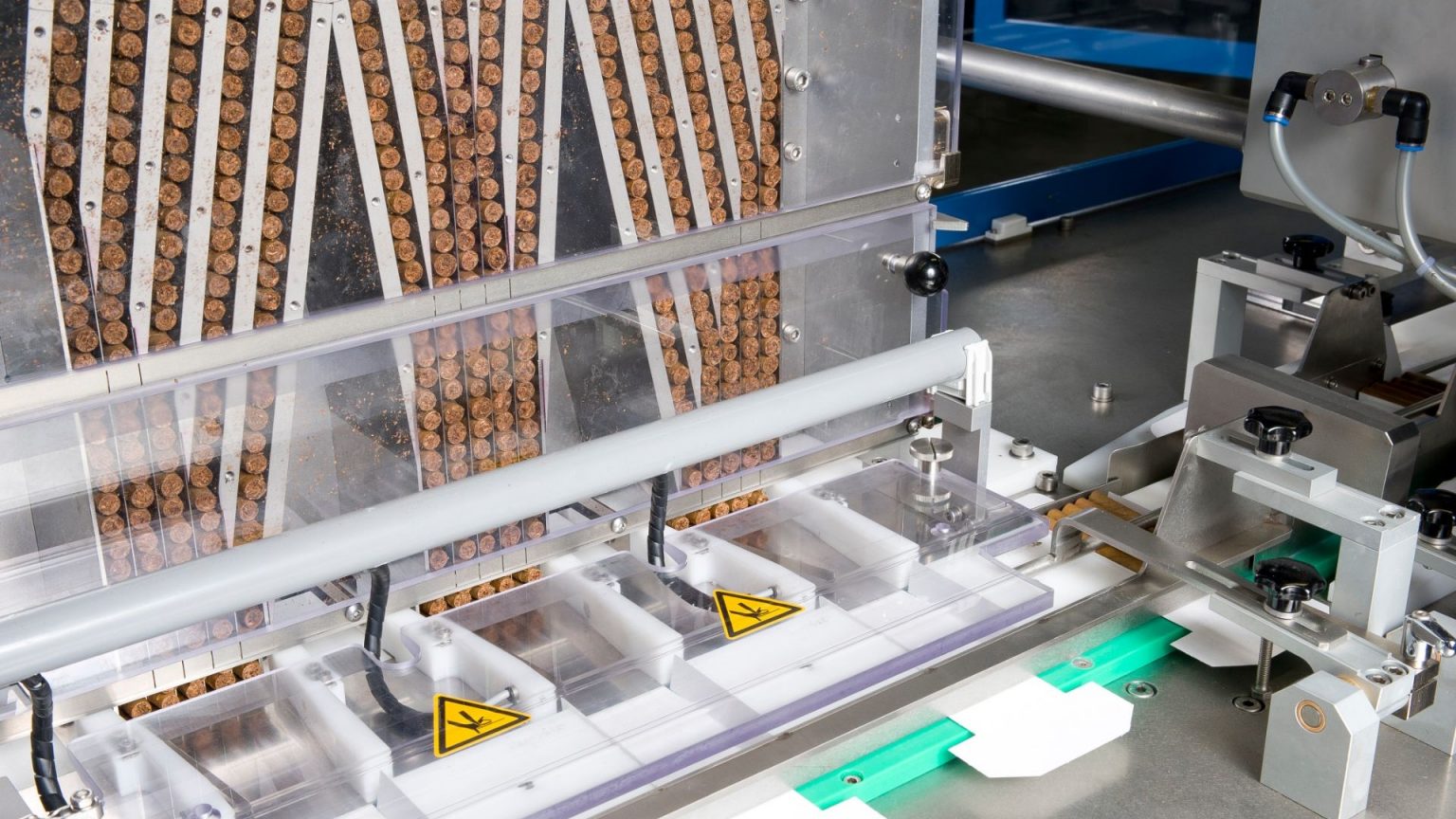

We use the same attention to detail when producing automatic labeling machines and packaging machines.

Market leader in the cigar industry

Are you searching for a high-quality machine to produce your cigars? Several machines are available for customization to suit your product needs. For instance, the Rolling Cutting Machine (RCM-S) cuts out the leaf and rolls it onto a spool or bobbin. The MK8 machine or the Variomat/Max can create cigar bunches, which when combined with the cutouts, can produce the final cigar. Additionally, we can integrate cigar production with packaging services.

See our packaging solutions

ATD Machinery has established itself as the market leader in the production of cigar production machinery. With over 55 years of experience in the industry, the company is known for its innovative technologies, high-quality equipment, and exceptional customer service. Their comprehensive range of solutions can be customized to meet the unique needs of each customer, and their commitment to sustainability sets them apart from their competitors. Overall, ATD Machinery is a trusted and reliable partner for cigar manufacturers worldwide.

ATD's cigar machines have numerous benefits, such as:

Increased efficiency

Cigar production machinery can significantly increase production output and efficiency, allowing for more cigars to be produced in a shorter amount of time and per kilogram tobacco.

Consistent quality

Cigar production machinery ensures that each cigar is made with the same level of quality and consistency, which is important for maintaining a strong brand reputation.

Cost savings

Investing in cigar production machinery results in long-term cost savings, as it reduces the need for manual labor and increases overall efficiency.

Customization

Some cigar production machinery can be customized to produce different types of cigars, which allows manufacturers to expand their product offerings and meet the needs of different customers.

Improved safety

Cigar production machinery improves worker safety by reducing the need for manual labor, which prevents from injuries and accidents. ATD is familiar with human interface production, a smooth and safe operation between human and machine.

ATD Machinery is a company that specializes in cigar production machinery, offering a range of machines that provides these benefits and more. Overall, cigar production machinery provides numerous benefits for manufacturers, and companies like ATD Machinery ensure that these benefits are realized.

Case Study

Read more about our solution for Imperial Brands here

Why choose ATD?

With our expertise and cutting-edge technology, We develop and build tailor-made solutions for more efficient production environments, machines, installations and services. We discuss your wishes, what the challenges are, and what the machine must comply with. We listen to your needs, and translate them into a machine. We are dedicated to delivering a machine of top-level quality that does everything you need it to. The question is never if we can build it, only how we can build it as effectively and user-friendly as possible. And after building it, we conduct a Factory Acceptance Test. If the result is satisfactory, the machine is ready to be delivered to you. Ready for production with demonstrably better results and lower production costs.

This ensures reliable and higher output allowing our partners to run their business more sustainable, cost-effectively and perform better than the competition.

Challenge us!

Do you want a top-quality machine that always performs?