MIR-A

Interested in our MIR-A machine?

Fill in your contact details and we will contact you as soon as possible.

The benefits

of using a MIR-A machine

- Ergonomic operating height

- Possibility for one way cutting (less wear of knives)

- Pressure in format chamber to be set in HMI operating panel

- Possibility for CE certification

- Less wear parts

About MIR-A

Bunch section (SW-A)

In the bunch section, where a controlled tobacco feeder, filler-chamber and rolling table are applied, the natural binder is safely cut, using servo controlled cutting-drives.

This increased safety feature, results in higher yield in cooperation with skilled operators. Bunches are pressed in temperature controlled pressing drums. The possibility to run process per process, really sets the new MIR apart!

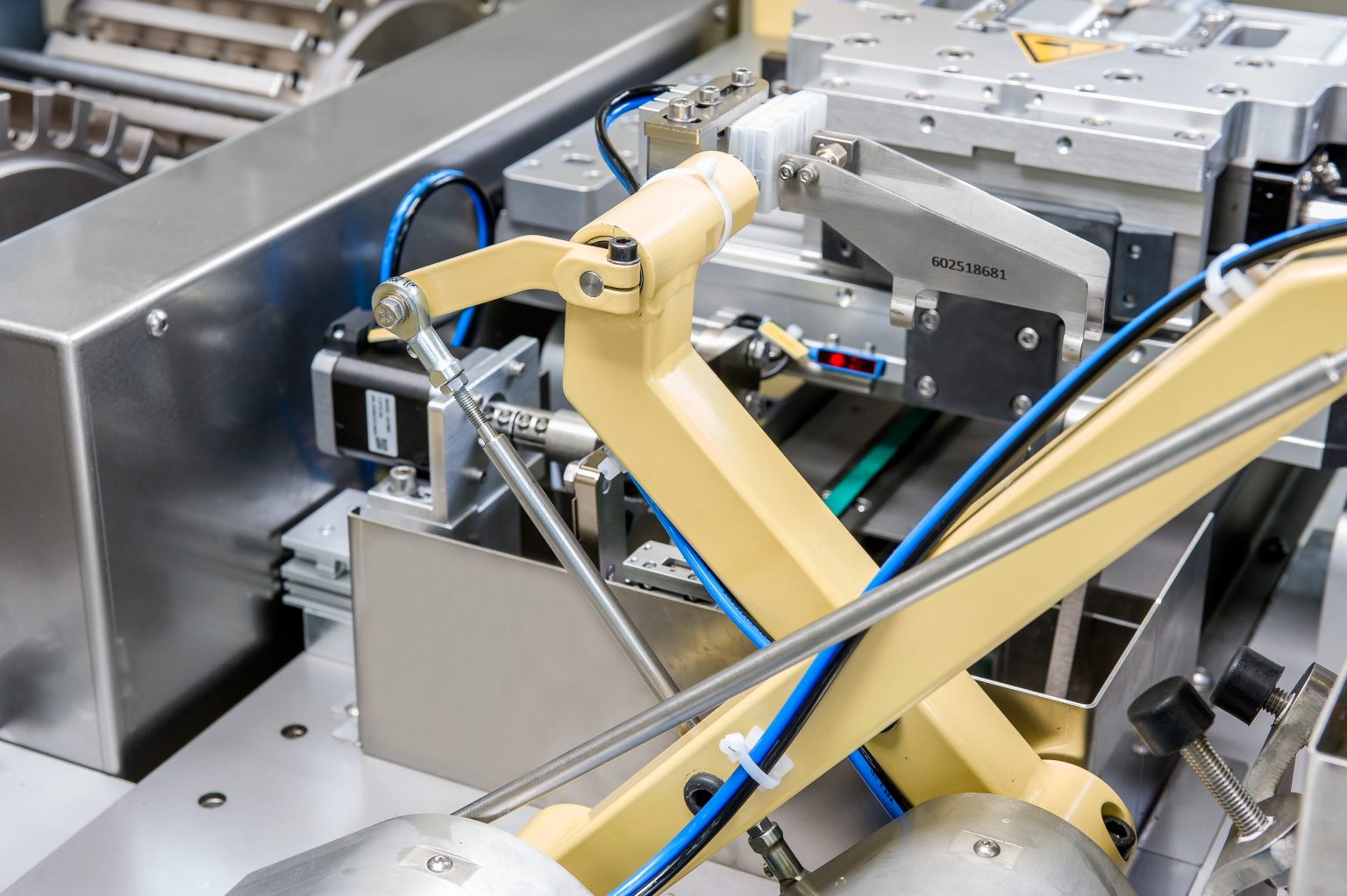

Overrolling section (MID)

A cutting device will shape the wrapper making it a perfect fit for the pre-made the bunch. When the cigar has been overrolled and cut to the required size a small gripper positions it on the discharge conveyor. All movements are controlled by servo drives!

The machine is supplied for a designated cigar model. Altering specific format parts allows for producing a different model. ATD designs the format parts, based on client specifications.

This easy to maintain machine, is typically carried out with a stainless steel rolling device with ceramic bearings, ensuring a long operating life. Besides the applied servo-techniques, PLC control and a HMI panel are installed as well.